Wire Mesh Feeding Machine for Gabion Machine/Gabion Mesh Machine

- Model

- NFM-4000

Item specifics

- Max. working width

- 5000mm

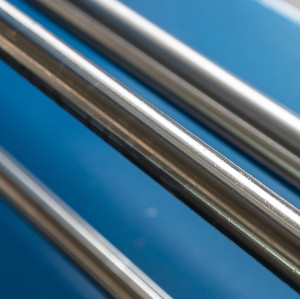

- Wire diameter

- ≤5mm

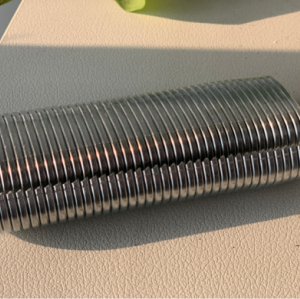

- Upper roll size

- Φ133mm * 3pcs

- Down roll size

- Φ133mm * 4pcs

- Straightening thickness

- ≤2.8mm

- Output

- 8.5m/minute

- Power

- 5.5KW

- Roller Speed

- 20turn/minute

- Weight

- 2.5T

- Size(LXWXH)

- 5550X1450X1400(mm)

Review

Description

Wire Mesh Feeding Machine Specifications

1 Max. working width 5000mm

2 Wire diameter ≤5mm

3 Upper roll size Φ133mm * 3pcs

4 Down roll size Φ133mm * 4pcs

5 Straightening thickness ≤2.8mm

6 Output 8.5m/minute

7 Power 5.5KW

8 Roller Speed 20turn/minute

9 Weight 2.5T

10 Size(LXWXH) 5550X1450X1400(mm)

11 Infrared ray meter counter

12 Wire stop device when the cutting machine cut the net

13 Frequency motor

Advantages of Wire Mesh Feeding Machine

The Wire Mesh Feeding Machine is one of significant auxiliary machines for the gabion production line. It straightens and feeds the wire mesh to the cutting machine, during this process, the machine ensure the evenness so that the gabion box could stay for a long time as possible.

The Wire Mesh Feeding Machine is pretty easy to operate and barely requires to maintenance. It is equipped with PLC and only needs to set several parameter, such as number of wire mesh or reduction ratio then it’d work automatically.

The Wire Mesh Feeding Machine is also equipped with wire stop device, it will not keep feeding until the cutting machine finished the cutting move.

Wire Mesh Feeding Machine Application Site

Wire Mesh Feeding Machine Products

Wire Mesh Feeding Machine FAQs

Q: What’s the distance between Wire Mesh Feeding Machine and wire mesh cutting machine?

A: Measure 2.5m at the front of the net winding machine where to put the net straightening machine. Pls make sure that it is parallel with net winding machine.

Q: What should be preparing for running this machine?

A: Feeding lubricating oil before starting machine. Then starting test running the machine around 10 mins without feeding net till it runs smooth.